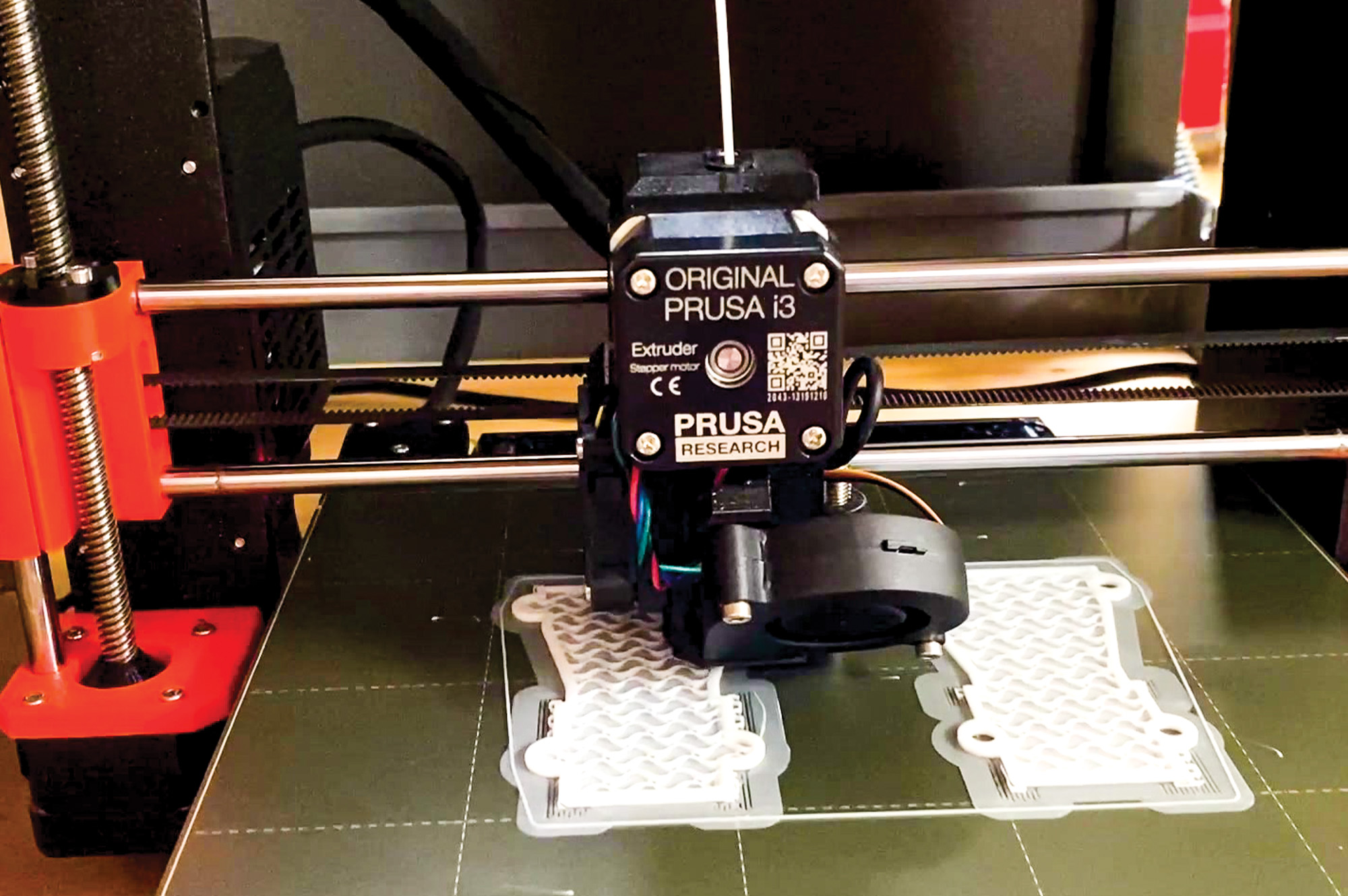

What could you do with $1000? Go on a shopping spree? Treat your friends to a lavish night on the town? How about using it to save lives? Well that’s exactly what Sarasota Memorial Hospital did. Last year, amidst the COVID-19 pandemic, when vital medical supplies and personal protective equipment such as CAPRs (controlled air-purifying respirators) were becoming increasingly difficult to source, SMH made a life changing purchase. With $1000, the hospital purchased a small 3D printer that would quickly become an essential tool in its arsenal. Using this tiny, yet powerful machine, SMH’s biomedical engineering team was able to create CAPR mounting tab replacements so that medical care providers would not have to rely on N95 masks—which can often be claustrophobic and lack eye coverage—to protect them from COVID-19 while treating infected patients. But that is far from the end of the story.

DIRECTOR OF TECHNOLOGY ASSESSMENT AND BIOMEDICAL ENGINEERING ROBERT SANTOS EXPLAINS HOW 3D PRINTING TECHNOLOGY WAS USED BY SMH DURING THE COVID-19 PANDEMIC

In the past year, Sarasota Memorial Hospital has been testing the waters with exactly what can be achieved with 3D printing in the medical field by using the innovative technology to create a more ergonomic environment for medical workers. Like many of us know, some of the most necessary and helpful things in life are those that can often be overlooked. This is true in the medical field as well—as SMH has discovered. The management of cables and hoses in the operating room is a major focus—these essential components deliver not only the anesthesia, but also life-sustaining gases and monitor the patient’s vitals. And because they can pose a tripping hazard in the O.R., SMH’s biomedical engineering team has been working on fixing this issue. “We’re trying to create different methods of holding those cables out of the way,” says Robert Santos, director of SMH’s Biomedical Engineering and Technology Assessment Department. “We even have a little clip that we designed that goes on the accessory rail of the surgical table. It’s a small plastic clip that hoses can hang on so they don’t go on the floor.” The biomedical engineering team has also been working on ways to reinforce the weak point in cables to reduce the risk of bending and breaking.

Since beginning its 3D printing journey last year, Sarasota Memorial Hospital has purchased a larger 3D printer—allowing them to create larger pieces—and most recently, a 3D scanner. This machine functions by taking a series of images of the item placed on its platform and then converting them into a CAD (computer-aided design) file that can be used as a template for creating a prototype. “Once an idea is received, we can usually have a prototype done in 24 to 48 hours,” says Santos. “We often have a quicker turnaround time than even Amazon Prime.”

This is just the beginning of what is to come. “We’ve only really scratched the surface in talking to some of the hospital’s leadership and discussing the technology,” he says. “We’ve been doing really simple, yet important, stuff for them.” Santos and his department believe that the next major step for SMH will be 3D metal printing, which while more expensive, will allow for the creation of more durable and long-lasting equipment.